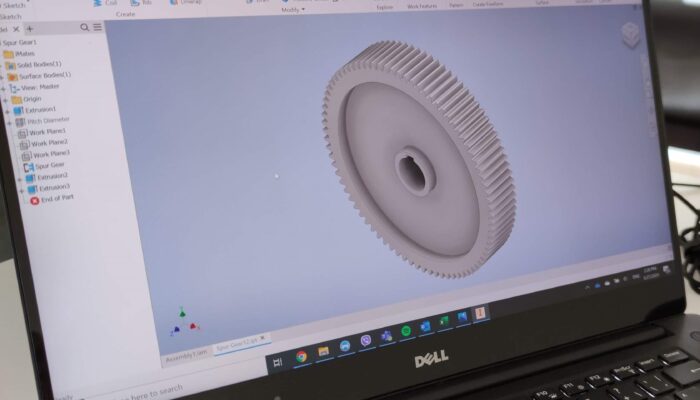

Millions of machine products and components are created every year by manufacturers all over the world. Many of these goods have stayed relevant for more than a few years after their original introduction. On the other hand, many old machine parts have been shown to be durable. You replace the component, not the entire product when it fails. These elements can be replaced using a method called reverse engineering.

Utilising the latest engineering and manufacturing technologies we are able to reproduce missing parts according to OEM specifications or with enhanced properties

When both of our restoration technologies are not suitable and it is not possible to restore the part, we use the option – reverse engineering. Reproducing missing parts according to OEM specification or enhanced properties anytime fits perfectly.

Adretec supports organizations by producing precision quality products with high tolerances and recreating the O.E.M. requirements using advanced 3D scanning technology and CNC photographic measuring equipment. This technology’s detailed reports and graphics serve as an official record of technical assessments and specifications.

Our machine shop services deliver high-quality bespoke components faster and for less money than the original manufacturer. We can reverse engineer products to the required tolerances or requirements, ensuring that you get the part when you need it.

If you have a part that you would like us to reverse-engineer or provide a price for, please contact us and provide us with further details.