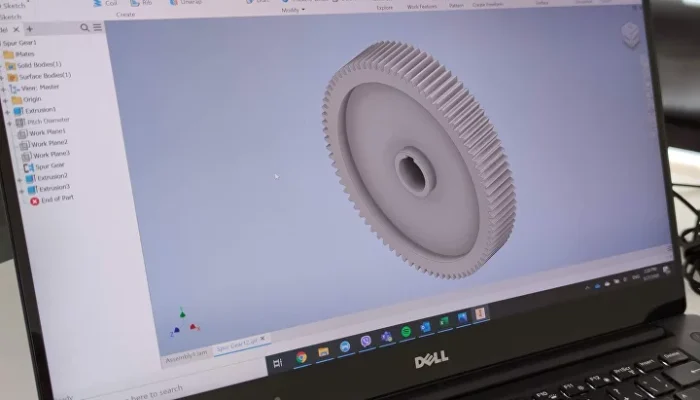

Reverse engineering, also referred to as back engineering, is the process of building a project from individual parts or goods without using drawings or other supporting materials. These components can be improved and modified to increase their lifespan or add new functions by creating a digital CAD model using 3D scanning.

With the appropriate reverse engineering tools, Adretec helps its customers at any stage of the product development process to deliver 3D CAD models and STL files.

- In general-purpose or native file formats, parametric 3D modelling;

- Hybrid modelling (design intent and as-built);

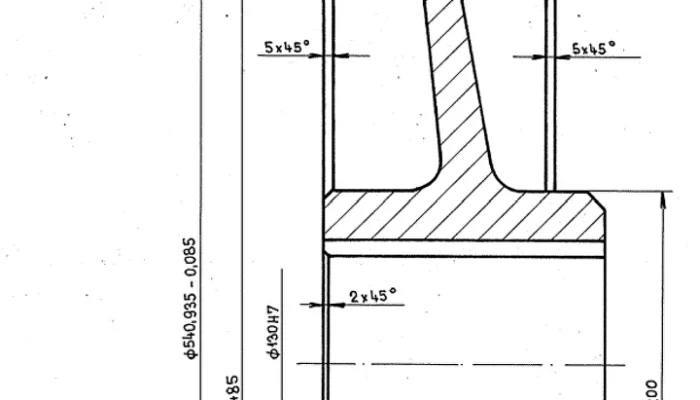

- Reconstruction using 2D drawings, sketches, 3D scanning data, etc.;

- 3D modelling of various sizes of items;

- Preparing data for a computer simulation;

- Class-B surfacing and advanced Class-A surface modelling;

The reverse engineering and retrofitting specialists at Adretec have a wealth of technical expertise in managing missing component design data, removing original design defects or failures, and improving manufacturing processes’ efficiency by generating 3D CAD models that are immediately usable (including freeform and NURBS surfaces).

Rely on Adretec’s competence in reverse engineering if you need to create 3D CAD models from existing items (as-built), whether to ascertain the original design intent, update production procedures, or create a new component to fit a legacy part, for example.