Welcome to Adretec, the trusted provider of on-site laser cladding solutions for a wide range of industries. With our cutting-edge laser technology and experienced technicians, we deliver efficient and precise cladding services that enhance performance and durability.

Whether you belong to the manufacturing, oil and gas, power generation, or marine industry, we have the expertise to cater to your unique needs. Enhanced Performance with On-Site Laser Cladding ( or IN-SITU ) in the Manufacturing Industry: Optimizing performance and extending the lifespan of components is crucial in manufacturing. Our mobile equipment brings advanced laser technology directly to your facility. Experience enhanced performance, reduced downtime, and improved durability through our tailored IN-SITU laser cladding solutions. Optimizing performance and extending the lifespan of components is surely crucial in manufacturing. Our on-site laser cladding services bring advanced laser technology directly to your facility. Experience enhanced performance, reduced downtime, while improved durability through our tailored on-site laser cladding solutions.

Durable Solutions for the Oil and Gas Industry:

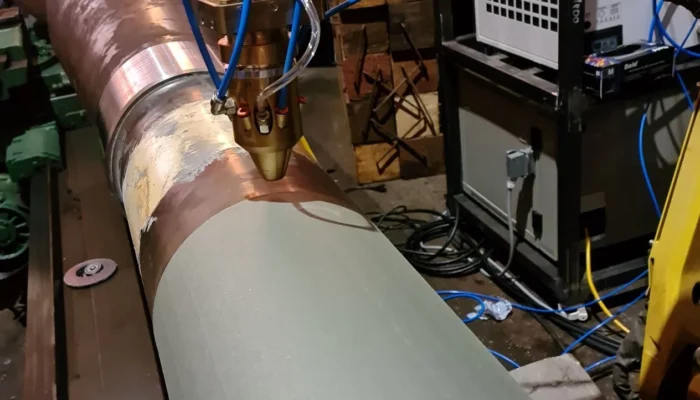

The oil and gas industry demands durable solutions for harsh operating conditions. Our IN-SITU laser cladding expertise also offers efficient repairs and refurbishments for critical components. Utilizing advanced laser technology, we ensure precise cladding that enhances durability, minimizing downtime and improving operational efficiency.

Optimized Power Generation Systems with IN-SITU Laser Cladding:

Maintaining optimal performance is essential in power generation. Our IN-SITU laser cladding services provide not only tailored solutions for turbine components and high-wear parts. By applying laser cladding techniques, we enhance surface properties, improving resistance to corrosion, erosion, and also wear. This results in an extended component lifespan and enhanced efficiency.

Reliable Cladding Solutions for the Marine Industry:

The marine industry requires reliable cladding solutions for the harsh marine environment. Our IN-SITU laser cladding services address specific needs, providing efficient cladding for critical components. By applying laser cladding, we surely enhance resistance to corrosion, erosion, and cavitation, ensuring extended service life and improved performance.

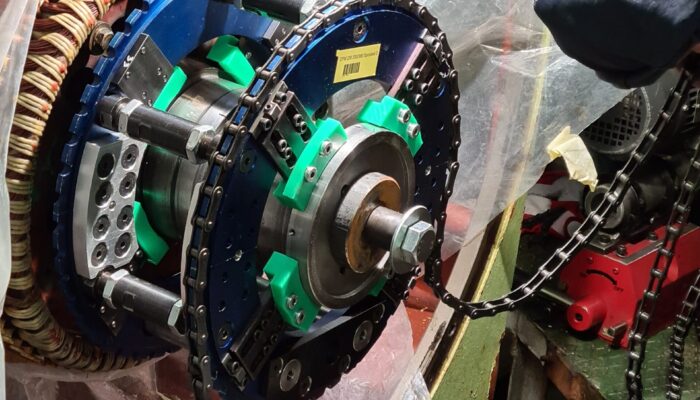

Another key point, all laser cladding processes are completely automated, guaranteeing precise and reproducible weld overlay application.

With the highest-quality laser processing hardware available, our laser cladding services department draws on our significant experience in the coating and also welding industries. We give the finest designed laser cladding solution for your wear and corrosion problem with our skilled laser cladding services.

In addition to laser cladding in the shop, we went further and created Laser Cladding equipment that is possible to deliver to any place either by plane or by road. Our on-site Laser Cladding equipment is possible to mount in any place to perform reconditioning of worn-out surfaces. On-site laser cladding provides faster and cost-efficient repair of expensive equipment or part within a few days with the result that without downtime.

Thanks to the robotic arm, reconditioning on-site is possible to perform even with complex geometries.

- Allows reconditioning of the surface of equipment both, on-site and in the workshop.

- Reduces downtime dismounting, logistics, and labor costs.